Author: Olivia Duffy – Lab Analyst

Laboratory reports are often confusing, filled with jargon that can be difficult to understand unless you know what you’re looking for. This article will walk you through a PAL report and explain what the purpose and meaning of each section is, as well as how to interpret the data there.

Cover Letter

The first page of a Precision Analytical Laboratories (PAL) Report is the cover letter, which describes the sample the lab received from you and what condition it was in when it arrived. This cover letter is especially important if you’ve submitted more than one sample; the cover letter will tell you what PAL Job Number has been assigned to each sample. The following pages will refer to your samples by PAL Job Number, so it’s important to know what number goes to what sample.

Sample Results

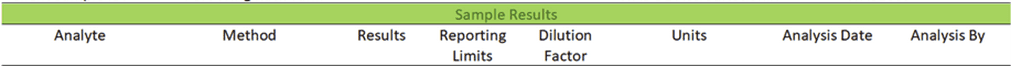

The next section(s) will have a header that says “Sample Results”; there will be a separate “Sample Results” section for each sample submitted. The PAL Job Number associated with each section can be found in the top right corner of that section, as well as some other information about the sample and analysis. The lab’s accreditation numbers can also be found here.

Below the header, you’ll find an array of columns that should have headings that look like this:

The “Analyte” column will list the contaminants you wanted your sample tested for.

The “Method” column will tell you what precise method we used to test for those contaminants.

The “Results” column will tell you what concentrations the contaminants were found in. Make sure you take a look at the Units column while reading your results; the units we use can change from one method to another. More information about units can be found below.

The “Reporting Limits” column will tell you the lowest concentration of contaminant that we can report. Anything that had a Result below this number won’t have a number in the “Results” column. If you need specific reporting limits for permitting, please make sure to reach out to us before submitting your sample so we can make sure to accommodate you. If you’re reading this after already receiving your report, and a reporting limit is too high, contact us anyways, we should be able to help!

The “Dilution Factor” column will tell you if we needed to dilute your sample during testing. To interpret this number, just imagine that the number listed is the bottom of a fraction. If the sample had a Dilution Factor of 10, the sample was read at 1/10 the concentration it actually is, or diluted with one part sample and nine parts diluent. The Result listed will have already taken the Dilution Factor into account, but it can be a helpful number to know. A higher Dilution Factor requires a higher Reporting Limit, so if we had to dilute your sample a lot, take a look at the Reporting Limit listed and make sure it’s acceptable for your needs.

The “Units” column will tell you what units the Results are listed in. If you have specific units you would like used in your report, please let us know! Below are some of the common units used and their definitions.

| Unit Listed | Unit Definition | Description | Example |

| µg/L | Micrograms per liter | There are one billion micrograms in a kilogram (which is about the mass of one liter of water). This unit of measurement is also sometimes referred to as “parts per billion”. | 1 µg/L: There is 1 µg of contaminant found in 1 liter of sample, or 1 part of contaminant found in 1 billion parts of sample |

| mg/L | Miligrams per liter | There are one million milligrams in a kilogram (which is about the mass of one liter of water). This unit of measurement is also sometimes referred to as “parts per million”. | 1 mg/L: There is 1 mg of contaminant found in 1 liter of sample, or 1 part of contaminant found in 1 million parts of sample |

| S.U. | Standard Units | This is the type of “unit” used for pH. | 7.5 S.U.: The pH is 7.5 |

| F | Fahrenheit | This is the default unit we use to report Flash Point results. The “Result” listed will have the temperature, in F, that the sample flashed at. | 132 F: The sample flashed at 132 degrees Fahrenheit. |

| mg/kg | Miligrams per kilogram | The description for “mg/L” also applies here, but these units are used for solids samples, rather than liquid. | 1 mg/kg: There is 1 mg of contaminant found in 1 kg of sample, or 1 part of contaminant per 1 million parts of sample. |

| µg/kg | Micrograms per kilogram | The description for “µg/L” also applies here, but these units are used for solids samples, rather than liquid. | 1 µg/kg: There is 1 µg of contaminant found in 1 kg of sample, or 1 part of contaminant per 1 billion parts of sample. |

| cSt | Centistokes | A centistoke is a centimeter-gram-second unit of kinematic viscosity. It is the most common unit used for this test. | 1 cSt: A sample with a kinematic viscosity of 1 cSt has a low kinematic viscosity. In other words, it’s not very viscous, and flows easily. |

| Count | Count per milliliter | The number of particles counted in one milliliter of sample. | >4 mm 200 Count: There are 200 particles that are larger than 4 mm diameter in one mL of sample. |

Laboratory Control Sample Results

The Laboratory Control Sample is a quality check that is run with every set of samples in almost every analysis. We know what the Result for this sample should be, so we test it with client samples to make sure that our analysis is working properly. The first two columns of this section (“Analyte” and “Method”) are the same as in the Sample Results section.

The “% Recovery” column tells you how close to the expected value the Laboratory Control Sample (or LCS) was. If the % Recovery is 100, the Result was exactly what was expected. There are dozens of small variables that affect each test, so having a recovery slightly above or below 100 is normal.

The “Qualifier” column is where you will find any flags listed for an analyte. There will be a complete list of flags and their meaning at the end of this article.

The “Limit” column contains the range of acceptable % Recovery for each analyte. This is usually determined by the method we use, or by our accrediting bodies. Any % Recovery that falls outside of this range will have a flag in the Qualifier column.

Laboratory Blank Results

A Laboratory Blank (or just Blank) is run with each set of samples for almost all analyses. This is a sample made by the lab that shouldn’t have any of the analytes we’re testing for in it, and is used to check for laboratory contamination during the analysis. If a Blank Result has a flag, that means some of that analyte got into the Blank during analysis somehow. This rarely happens, but occasionally a sample with a very high concentration of an analyte can contaminate the blank, or a reagent used during analysis can become contaminated.

Sample Duplicate Results

Some of our analyses require that we analyze a duplicate of your sample. This means we take a second sampling of the sample you give us and analyze it to see how closely it matches the first sampling.

All of the columns in this section are described in other sections, except for “RPD”, or Relative Percent Difference. This is how different the Result for a sample is from its Duplicate. If the RPD is higher than we expect it to be, meaning the two samplings are more different from each other than expected, there will be a flag in the “Qualifier” column. Solid samples, liquid samples that are chunky or contain floating bits, or samples that have visible layers are often nonhomogeneous, and may have flags for some analytes. If you see a flag in this section, compare the Results of the sample and duplicate to get an understanding of the range of concentrations that exist in your sample.

Matrix Spike Sample Results

A Matrix Spike Sample (or MS) and a Matrix Spike Duplicate (MSD) are required for some of our liquid sample analyses. A Matrix Spike is when we take a sampling of your sample, and add known concentrations of the analytes we’re testing for. Then we analyze that sample to see if the “spikes” of analytes we added are still there. This tests for something called matrix interferences.

A matrix interference is something that makes it hard to get an accurate reading on an analyte in a sample. It could be something that destroys the thing we’re looking for, so that it’s no longer present in the sample (for example, chlorine can destroy cyanide when they’re in a solution together). Other matrix interferences could be compounds that break down into the analyte we’re testing for during the process of analysis, or that our instrumentation mistakes for the analyte, both of which would cause an inaccurately high result.

Precision Analytical Laboratories does everything we can to remove interferences during analysis, but sometimes a sample will have interferents that we can’t remove. The MS and MSD help us detect these interferents.

If the % Recovery or RPD for an analyte is outside the acceptable range, there may be an interferent causing a false result.

Surrogates

Surrogates are known amounts of analytes that we add to samples, that aren’t what we’re actually testing for, but are similar to the things we are testing for. We use surrogates in some analyses to make sure that the “recovery” of the sample analytes is acceptable (in other words, that we’re analyzing the concentrations in the sample accurately).

A high surrogate % Recovery means that the sample analyzed was more concentrated than the original sample, and a low surrogate % Recovery means that some portion of the potential contaminants in the sample may have been lost during analysis. Surrogates can have a wide range of acceptable % Recoveries, especially for analytes that are particularly volatile. All of our listed ranges of acceptable surrogate % Recoveries are determined by the methods we are accredited for.

Flags

A Result will be flagged if something about it isn’t what it was expected to be. Most flags are minor and don’t greatly affect the sample results, since we retest any samples that have any major issues. Some permits, however, can be specific about what kinds of flags are or aren’t acceptable, so it’s important to look over your permit if you’re unsure about a flag. If your results will have a flag indicating they may not be accurate, we will reach out to you to confirm that it’s acceptable. If it’s not, we’ll work with you to resample and/or retest the sample.

| Flag or Qualifier | Meaning |

| U | The analyte was analyzed for, but not detected at or above the reporting limit. |

| J | The analyte was detected above our Method Detection Limit, but below our Reporting limit. This means that the analyte exists in the sample, but in a small enough amount that we couldn’t report the concentration. |

| E | The Duplicate of a sample had an RPD outside of the acceptable range, implying that the sample was nonhomogenous. |

| T | The sample was received by the lab later than 24 hours after sampling, and the sample was not kept between 0-6 degrees Celcius. Samples not being properly temperature preserved can affect the sample results. |

| N | The Result for this sample is an estimate. This flag is usually used for analytes outside of what we are accredited for, or it may be present if you only want something tested for presence/absence. |

| MS-01 | The spike recovery and/or RPD was outside acceptance limits due to possible matrix interference. |

| MS-02 | Matrix spike % Recovery and RPD calculations aren’t required because the amount spiked is too small compared to the concentration of the analyte in the sample, so it won’t be a helpful comparison. |

| Y | There is contamination in the laboratory blank, this contamination is most likely from the laboratory, or from an extremely concentrated sample. |

| L | Laboratory control sample recovery was outside acceptable limits, this may indicate biased results in the analysis. |

| S | Sample size submitted to the laboratory was insufficient for the analysis requested so the reporting limit of the sample required adjustments |

| H | The sample was analyzed or received by the laboratory outside of the acceptable hold time for the analysis requested. |

| ND | No flash was detected for flash point analysis. |

Precision Analytical Labs is a leading provider of comprehensive environmental testing services, specializing in wastewater testing, soil analysis, and air quality monitoring. With state-of-the-art facilities and a team of experienced professionals, we deliver accurate and reliable results to help businesses and industries comply with regulatory standards and protect the environment. Our commitment to quality and customer satisfaction sets us apart, making us the trusted partner for all environmental testing needs.